RELIABLE AND SAFE:

FREQUENCY PRODUCTS AND

BATTERY SOLUTIONS FROM JAUCH

JAUCH BLOG

Rhythm and energy are the forces that move and drive the world. Our world at Jauch is particularly influenced by these impulses. Frequency control products and battery solutions determine our everyday life and give us rhythm and energy every day. Above all, our employees are the factors which make Jauch a very special company.

In our blog we will take you on a journey through our products, employees and the Jauch corporate culture to give you exciting insights behind the scenes of the Jauch Group. We look forward to sharing with you!

Stay cool when it gets hot: Frequency control products from Jauch for high-temperature environments

As temperatures rise and the sun beats down on technology, it’s not only people who feel the heat – electronic components must also perform at their best. Frequency control products, such as quartz crystals and oscillators, are particularly critical in this regard. They ensure precise timing in countless applications – from GPS and Wi-Fi to

- Published in Frequency Control Products

Lasting success: Jauch shines with silver

We have good news! Jauch Quartz GmbH has been awarded the Silver Medal by EcoVadis, the globally recognized platform for sustainability assessments. This places us among the top 15% of all participating companies! Before we look at this great result in detail, let’s first consider a fundamental question: Why do companies need a “sustainability certificate”

- Published in The Company

Long service life and maximum frequency stability for insulin pumps and CGM systems

In Germany, around 400,000 people currently suffer from type 1 diabetes. Of these, around 35,000 children and young adults up to the age of 18 are affected. But what does the diagnosis “type 1 diabetes” actually mean? And what do diabetics need to consider after receiving their diagnosis? Which devices and systems help diabetics to

- Published in Battery Technology, Frequency Control Products

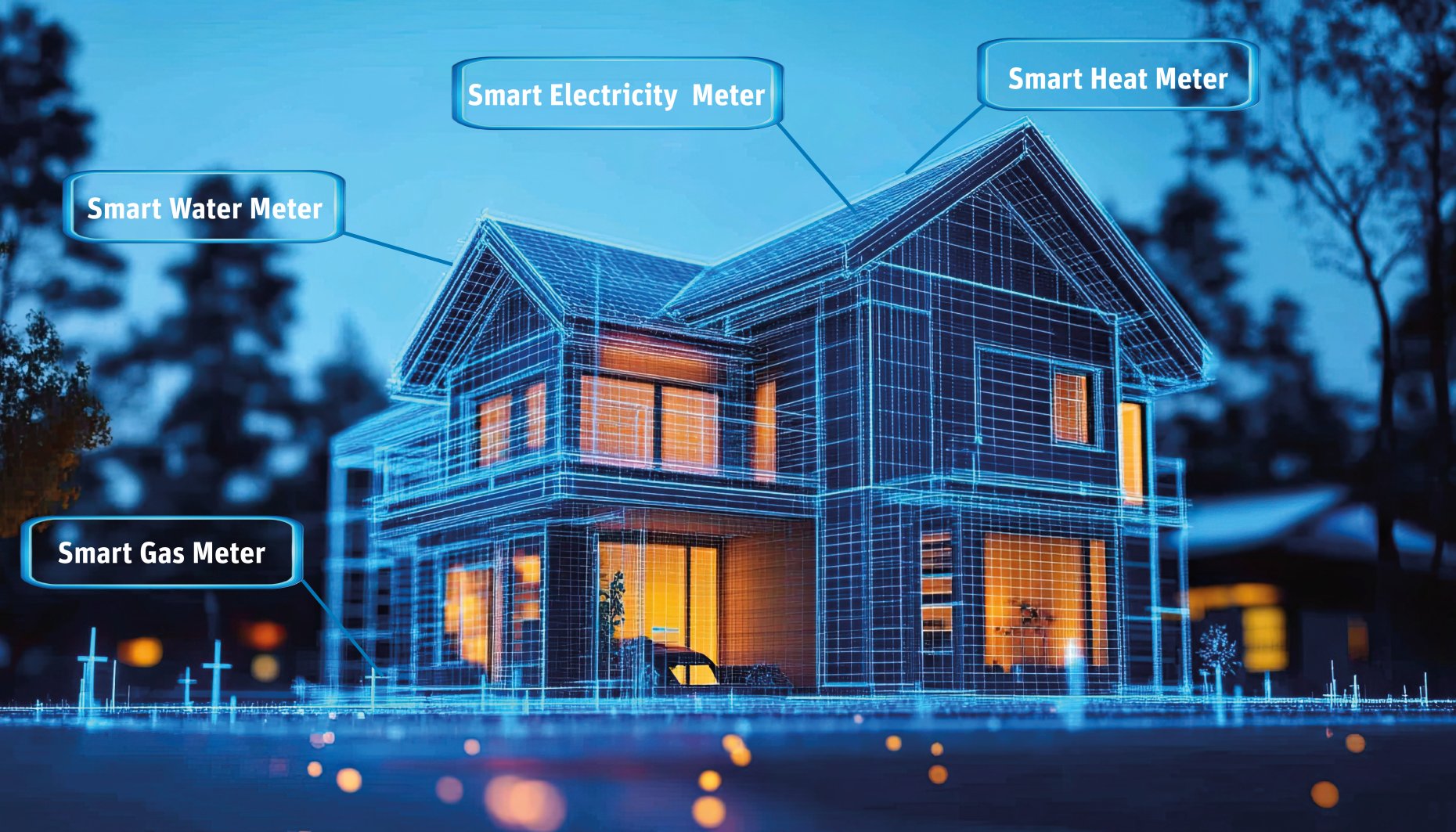

Why smart metering is the future of energy supply and why nothing works in this area without reliable frequency components and stable power sources

Everyone is talking about “smart metering”. But what exactly is this buzzword all about? And why would this technology be pretty much useless without frequency-stable clocks and reliable power sources? By “smart metering”, we are talking about a technology that monitors and analyzes energy consumption in residential and commercial facilities in real time. “Smart meters”

- Published in Battery Technology, Frequency Control Products

Dedication, hard work and unrelenting commitment pave the way to becoming a “champion”

The title of “Champion” is only awarded, both privately and professionally, to those who have proven over a long period of time that they belong to the absolute top in their field. The title of “Champion” has been achieved through a high degree of perseverance, commitment and discipline. A title that attests to the person

- Published in The Company

One Year of the New European battery Regulation EU 2023/1542 – Interview with Sönke Zacher

One year ago in February 2024 the new European Battery Regulation EU 2023/1542 came into force. What impact does the new regulation have on everyone who deals with batteries in their daily lives? We spoke with Sönke Zacher, Head of Project Management at Jauch: Sönke Zacher: The new battery regulation brings many innovations. It was

- Published in Battery Technology

The New European Battery Regulation EU 2023/1542: What You Need to Know

Did you know that the new European Battery Regulation came into effect last year? This regulation, officially known as “Battery Regulation EU 2023/1542,” introduces numerous changes and higher standards for the sustainability, performance, and labelling of batteries. The new Battery Regulation was published on 28th July 2023, came into force on 17th August 2023, and

- Published in Battery Technology

New test and certification center for cells and batteries: Jauch strengthens its role as a development partner

Lithium ion batteries are indispensable for modern, mobile applications, offering high energy density, compact design and a multitude of technical advantages. However, the complexity of safety and approval procedures poses significant challenges for companies developing battery-powered devices. This is precisely where Jauch comes in, with its new test and certification center at the company headquarters

- Published in Battery Technology

Long service life and maximum frequency stability for insulin pumps and CGM systems

In Germany, around 400,000 people currently suffer from type 1 diabetes. Of these, around 35,000 children and young adults up to the age of 18 are affected. But what does the diagnosis “type 1 diabetes” actually mean? And what do diabetics need to consider after receiving their diagnosis? Which devices and systems help diabetics to

- Published in Battery Technology, Frequency Control Products

Why smart metering is the future of energy supply and why nothing works in this area without reliable frequency components and stable power sources

Everyone is talking about “smart metering”. But what exactly is this buzzword all about? And why would this technology be pretty much useless without frequency-stable clocks and reliable power sources? By “smart metering”, we are talking about a technology that monitors and analyzes energy consumption in residential and commercial facilities in real time. “Smart meters”

- Published in Battery Technology, Frequency Control Products

One Year of the New European battery Regulation EU 2023/1542 – Interview with Sönke Zacher

One year ago in February 2024 the new European Battery Regulation EU 2023/1542 came into force. What impact does the new regulation have on everyone who deals with batteries in their daily lives? We spoke with Sönke Zacher, Head of Project Management at Jauch: Sönke Zacher: The new battery regulation brings many innovations. It was

- Published in Battery Technology

The New European Battery Regulation EU 2023/1542: What You Need to Know

Did you know that the new European Battery Regulation came into effect last year? This regulation, officially known as “Battery Regulation EU 2023/1542,” introduces numerous changes and higher standards for the sustainability, performance, and labelling of batteries. The new Battery Regulation was published on 28th July 2023, came into force on 17th August 2023, and

- Published in Battery Technology

New test and certification center for cells and batteries: Jauch strengthens its role as a development partner

Lithium ion batteries are indispensable for modern, mobile applications, offering high energy density, compact design and a multitude of technical advantages. However, the complexity of safety and approval procedures poses significant challenges for companies developing battery-powered devices. This is precisely where Jauch comes in, with its new test and certification center at the company headquarters

- Published in Battery Technology

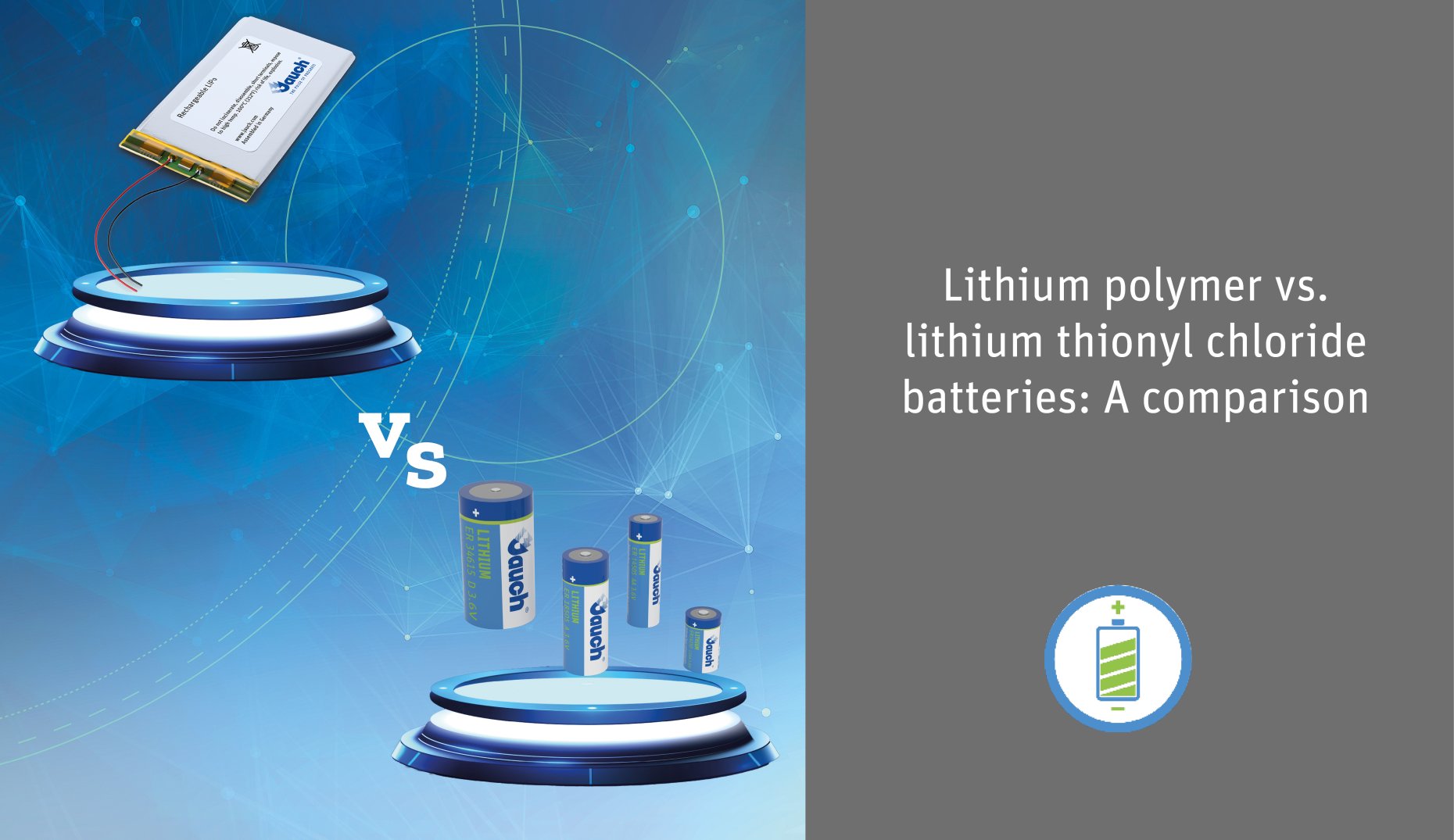

Lithium polymer vs. lithium thionyl chloride batteries: a comparison

In a world where the demand for powerful and long-lasting batteries is constantly growing, different technologies are competing to meet the needs of a wide range of applications. Among the promising options, rechargeable lithium polymer batteries and primary lithium thionyl chloride batteries are at the top of the list. Both are lithium batteries and are

- Published in Battery Technology, Uncategorized

Hot, hotter, battery problems? How to protect your battery-powered devices in summer

Summer is now slowly getting underway in Germany and we are all looking forward to the high temperatures. But have you ever thought about what this means for your battery-powered device? The heat has a significant impact on the performance and lifespan of batteries in portable devices such as smartphones, laptops and cameras. In this

- Published in Battery Technology

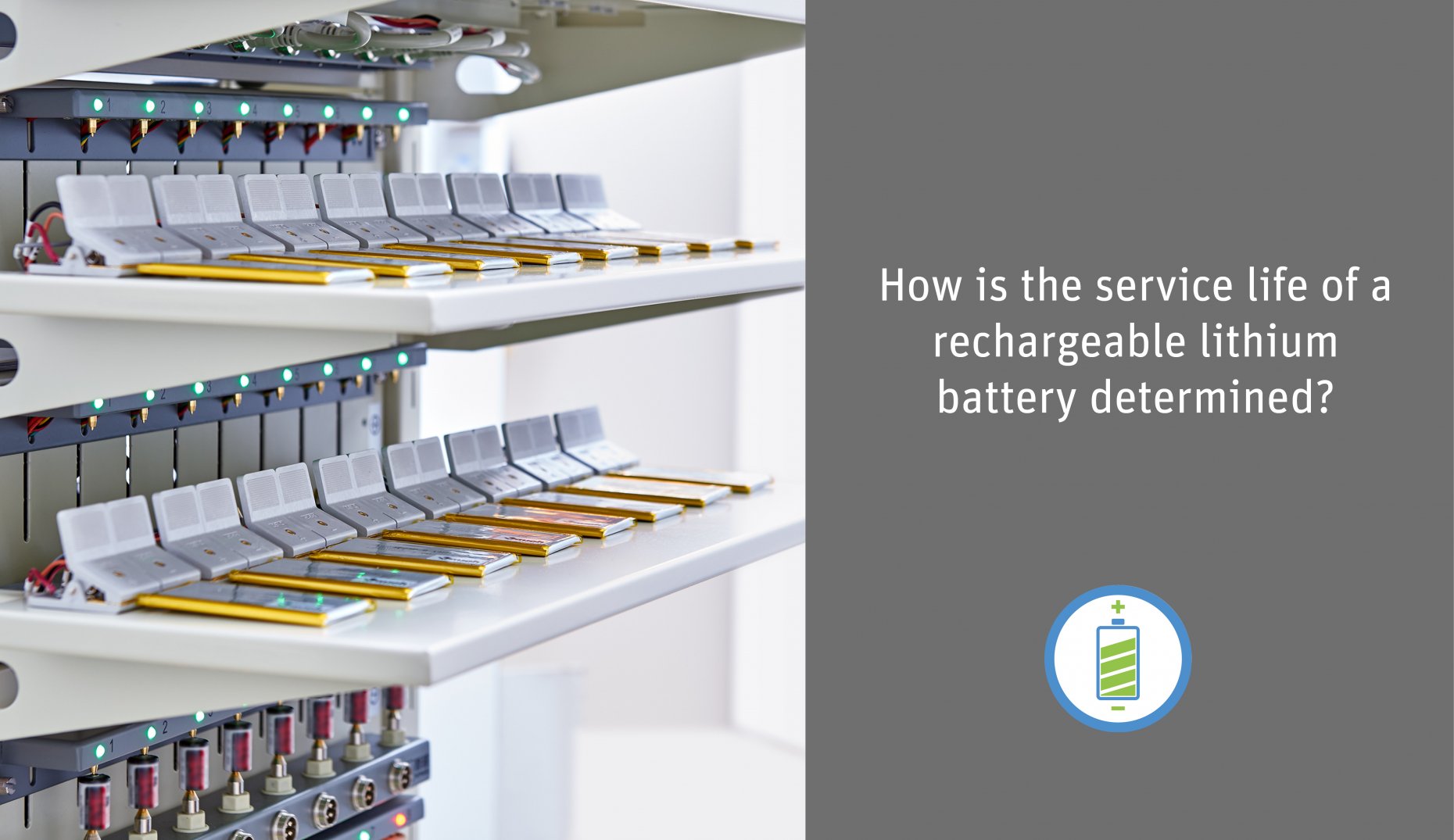

How is the life of a rechargeable battery determined?

Have you ever wondered why you have to recharge your smartphone battery at increasingly shorter intervals after 1 to 2 years of use? Of course, the phenomenon is not limited to the battery in the smartphone – every rechargeable battery inevitably loses storage capacity over time. But what is the reason for this? And how

- Published in Battery Technology

Stay cool when it gets hot: Frequency control products from Jauch for high-temperature environments

As temperatures rise and the sun beats down on technology, it’s not only people who feel the heat – electronic components must also perform at their best. Frequency control products, such as quartz crystals and oscillators, are particularly critical in this regard. They ensure precise timing in countless applications – from GPS and Wi-Fi to

- Published in Frequency Control Products

Long service life and maximum frequency stability for insulin pumps and CGM systems

In Germany, around 400,000 people currently suffer from type 1 diabetes. Of these, around 35,000 children and young adults up to the age of 18 are affected. But what does the diagnosis “type 1 diabetes” actually mean? And what do diabetics need to consider after receiving their diagnosis? Which devices and systems help diabetics to

- Published in Battery Technology, Frequency Control Products

Why smart metering is the future of energy supply and why nothing works in this area without reliable frequency components and stable power sources

Everyone is talking about “smart metering”. But what exactly is this buzzword all about? And why would this technology be pretty much useless without frequency-stable clocks and reliable power sources? By “smart metering”, we are talking about a technology that monitors and analyzes energy consumption in residential and commercial facilities in real time. “Smart meters”

- Published in Battery Technology, Frequency Control Products

Customer Success Story: Highest frequency stability for the tire pressure monitoring system sensor from TireCheck

A sensor that increases the safety of truck drivers and has a positive effect on the sustainability of tires – this is the mission pursued by TireCheck, a company specializing in the manufacture of tire management systems and tire pressure sensors for commercial vehicles. The product: the belt-mounted TPMS sensor One notable innovation from TireCheck

- Published in Customer Success Stories, Frequency Control Products

Ask the tech department: How thick is a quartz blank of 40 MHz?

Let’s start this blog post with a little quiz: Guess for yourself – the solution will come in the text. How thick is a quartz blank of 40 MHz? As thick as.. Guess for yourself – the solution will come in the text. But first, let’s take a look at the theory: Generally speaking, there

- Published in Frequency Control Products, Frequency Control Products

Stratum layers: an example for their necessity

It is Monday morning at 9:30 am. A selling order is placed on the exchange. Immediately after, two buying orders arrive for it. But there can only be one buyer. Who was faster and is eligible? How is fairness assured, and guaranteed without any risk of collision? The trading of shares determines the actions on

- Published in Frequency Control Products

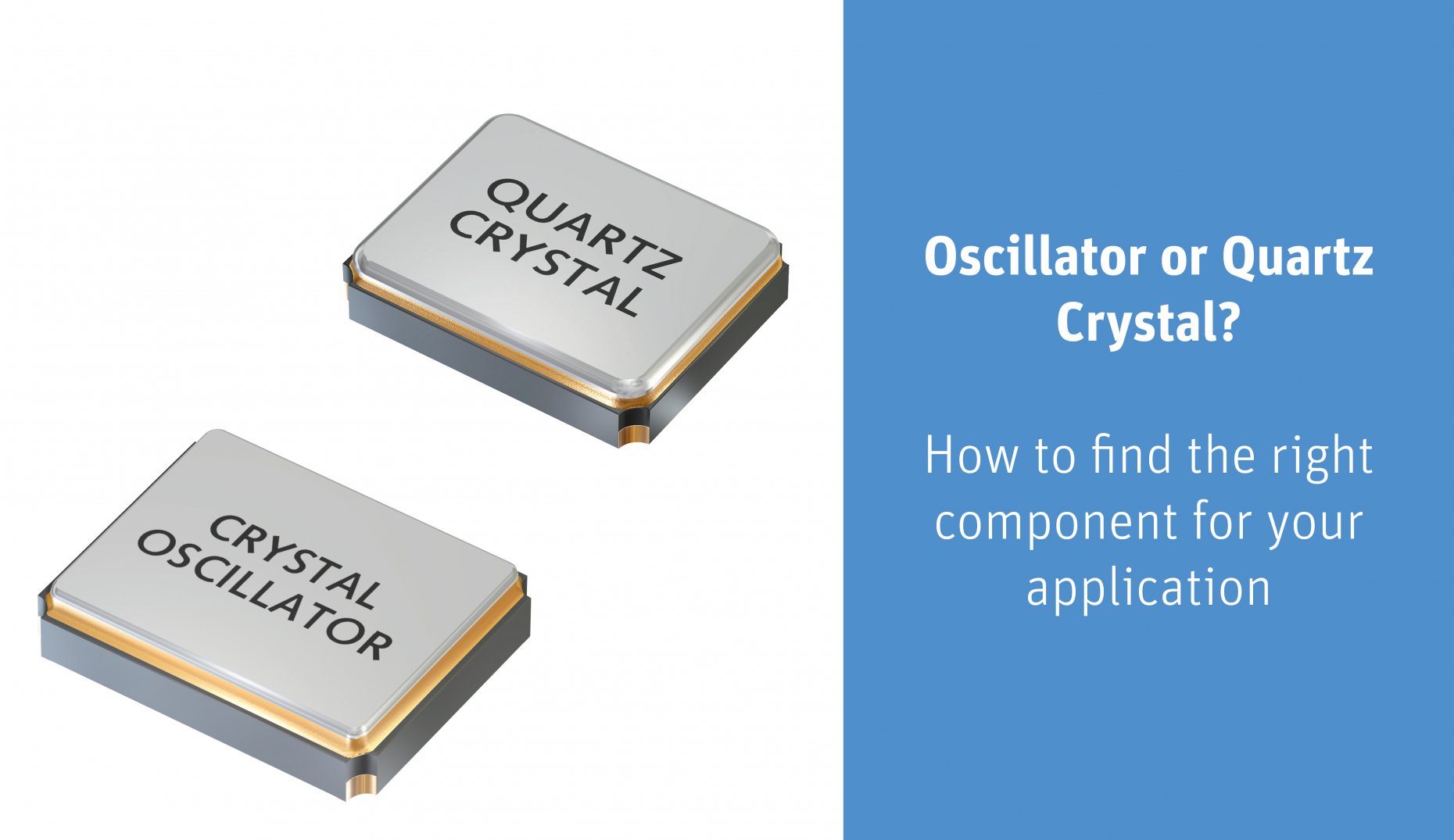

Oscillator or Quartz Crystal? How to find the right component for your application

In developing an electronic assembly, one of the steps involved includes choosing the appropriate frequency control product. The basic question at the outset is whether to install a quartz crystal or an oscillator. To reach the right decision, several parameters need to be considered. These include the many different requirements of the application, the device,

- Published in Frequency Control Products

Quartz Crystals and Oscillators in the Digitalization Trend

For several years now the term ‘Internet of Things’ has been in common parlance. Devices that are part of the ‘IoT’ can communicate with each other wirelessly. This is generally achieved using current standards such as WiFi, Bluetooth, Zigbee, and 5G. The Internet of Things also changes the requirements placed on the devices themselves. Today

- Published in Frequency Control Products

Customer Success Story: Highest frequency stability for the tire pressure monitoring system sensor from TireCheck

A sensor that increases the safety of truck drivers and has a positive effect on the sustainability of tires – this is the mission pursued by TireCheck, a company specializing in the manufacture of tire management systems and tire pressure sensors for commercial vehicles. The product: the belt-mounted TPMS sensor One notable innovation from TireCheck

- Published in Customer Success Stories, Frequency Control Products

Customer Success Story: Lunch from the mini-steamer – thanks to battery power from anywhere

Long lines at the microwave in the university canteen, a short lunch break and then the food also loses its taste and vitamins. For the trio of founders of the start-up Nexenic, this was the reason to revolutionize the topic of Mealprep. The product: the Steasy® mobile mini-steamer With Steasy®, food can be heated up

Customer Success Story: Reliable Power Supply for Epilepsy Detection during Sleep

Approximately 1 percent of people worldwide suffer from epilepsy. In numbers, that’s one in 100 to one in 150 people. In 30 percent of them, the disease is even incurable. This means that they are unable to control their seizures with the help of medication. Recurrent seizures are the result. “Seizures that occur during sleep

- Published in Battery Technology, Customer Success Stories

Customer Success Story: A durable and certified battery for mBrainTrain’s mobile EEG

Electroencephalography, or EEG for short, is a methodology for measuring tiny brain signals that are quite difficult to capture. You can likely imagine how these tests look like: Participants have electrodes and lots of cables around their heads while being in a lab. However, these complex systems cannot measure the human brain in the natural

- Published in Battery Technology, Customer Success Stories

Customer Success Story: The battery powered motorized positioning arm from Interventional Systems

In minimally invasive interventions, it is very important to work as accurately as possible. The motorized arm for the positioning and holding of medical equipment from the Austrian company Interventional Systems (INS) supports doctors during these interventions. Powered by a Jauch battery, it makes positioning and repositioning instruments easier than ever while keeping them steady.

- Published in Battery Technology, Customer Success Stories

Customer Success Story: The tripod for thermal imaging and night vision cameras – a lithium-ion battery for XSPECTER

Founded in October – and on the market within just six months: Start-up XSPECTER has its T-CROW XRII to thank for this success. The product behind this futuristic name is a special tripod for thermal imaging and night vision cameras. The product: A controllable 3D-printed camera tripod The T-CROW XRII is a controllable camera tripod

- Published in Battery Technology, Customer Success Stories

Customer Success Story: Thermal Imaging Cameras for Firefighters – A Robust Lithium Iron Phosphate Battery Pack for Leader Photonics

Everybody knows the emergency number for the fire department. And probably everyone hopes they are never forced to dial it. But in fact, this happens more often than you might think. This is shown by current statistics from the German Fire Brigade Association. According to these, the fire department was called out around 700 times

- Published in Battery Technology, Customer Success Stories

Customer Success Story: Why Millo Appliances Rely on Jauch – Twice

“If Apple made a blender, this would be it” – the British-American online news portal Mashable nailed it. When it comes to aesthetics and product design, the blender “Millo”, created by the Lithuanian start-up Millo Appliances, is very close to the great idol from Cupertino. Besides its award-winning design, the technology behind “Millo” is particularly

- Published in Battery Technology, Customer Success Stories, Frequency Control Products

- 1

- 2

Lasting success: Jauch shines with silver

We have good news! Jauch Quartz GmbH has been awarded the Silver Medal by EcoVadis, the globally recognized platform for sustainability assessments. This places us among the top 15% of all participating companies! Before we look at this great result in detail, let’s first consider a fundamental question: Why do companies need a “sustainability certificate”

- Published in The Company

Dedication, hard work and unrelenting commitment pave the way to becoming a “champion”

The title of “Champion” is only awarded, both privately and professionally, to those who have proven over a long period of time that they belong to the absolute top in their field. The title of “Champion” has been achieved through a high degree of perseverance, commitment and discipline. A title that attests to the person

- Published in The Company

Jauch Quartz GmbH celebrates 70 years of success and innovation

Jauch Quartz GmbH from Villingen-Schwenningen is celebrating an important anniversary this month: 70 years of successful company history. The company was founded on July 1, 1954 by Herbert Christian Jauch and entered in the commercial register of the town of Schwenningen. Today, the company is managed by Thomas Jauch, the son of the founder, who

- Published in The Company

Apprenticeship experience: A glimpse behind the scenes of training at Jauch

The start of an apprenticeship is an exciting time, full of new impressions, challenges, and opportunities for professional and personal development. We are Vivienne, Max, and Lucia, we are in the second year of our training, and we would like to give you an insight into our daily training routine at Jauch. An exciting beginning

- Published in The Company

Achieving company objectives with the OKR method

A few people are standing in front of a large whiteboard in the meeting room. The sales department, two OKR Masters and a member of the management board, look at colorful index cards on which objectives are noted. Individual objectives are explained while the colleagues from Sales listen intently. Then the discussion starts: what contribution

- Published in The Company

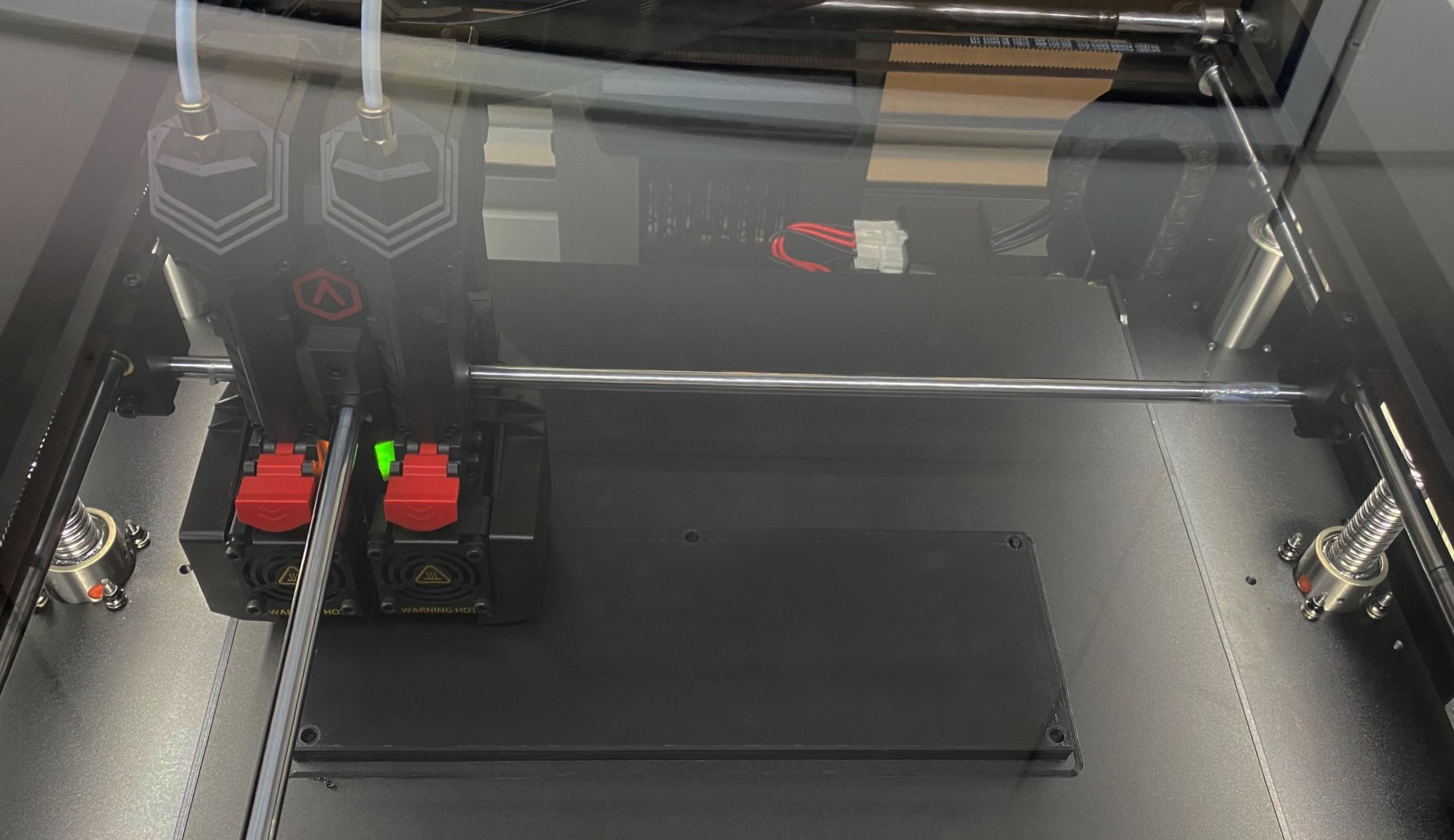

Creating a prototype in a short time – with the 3D printer

A new machine is improving our sample and prototype construction in Villingen-Schwenningen – although calling it a ‘machine’ may be stretching it 😊. Instead, what we have is a 3D printer, which brings a number of advantages: both our customers and our own in-house staff now benefit from greater speed and flexibility when it comes

- Published in The Company

With Lean Management and the 5-S method to more efficiency

The topic of permanent development has a high priority at Jauch. Not only with regard to our products and services, but also internally we are continuously working on it. During the last months, as an example, we have further developed the Logistics department (Incoming Goods, Warehouse and Shipping) and implemented new working methods and processes.

- Published in The Company

No Sign of Saturation – Even After 65 Years

The Jauch Group has grown alongside their frequency control products and – with their early entry into the battery technology market – they are now working in two promising growth areas. “On the 65th anniversary of the company, the signs still point to further expansion,” said Managing Director Thomas Jauch. 65 years ago, Herbert Christian

- Published in The Company

- 1

- 2

YOU CAN ALSO FIND US ON SOCIAL MEDIA

THE JAUCH SPECIALISTS ARE HAPPY TO ASSIST YOU!

PHONE

Frequency Control Components: 0049 77 20 / 9 45-322

Battery Technology: 0049 77 20 / 9 45-323

Corporate Headquarters: 0049 77 20 / 9 45-0

ADDRESS

Jauch Quartz GmbH

In der Lache 24

78056 Villingen-Schwenningen

Germany

Deutsch

Deutsch