In developing an electronic assembly, one of the steps involved includes choosing the appropriate frequency control product. The basic question at the outset is whether to install a quartz crystal or an oscillator. To reach the right decision, several parameters need to be considered. These include the many different requirements of the application, the device, or the industry. In addition to space requirements, frequency stability, and expertise, development costs also play a notable role.

Quartz crystal or oscillator? That is the question! In the following, we’ll take a closer look at situations when one component or the other is the better choice:

When a quartz crystal is the way to go

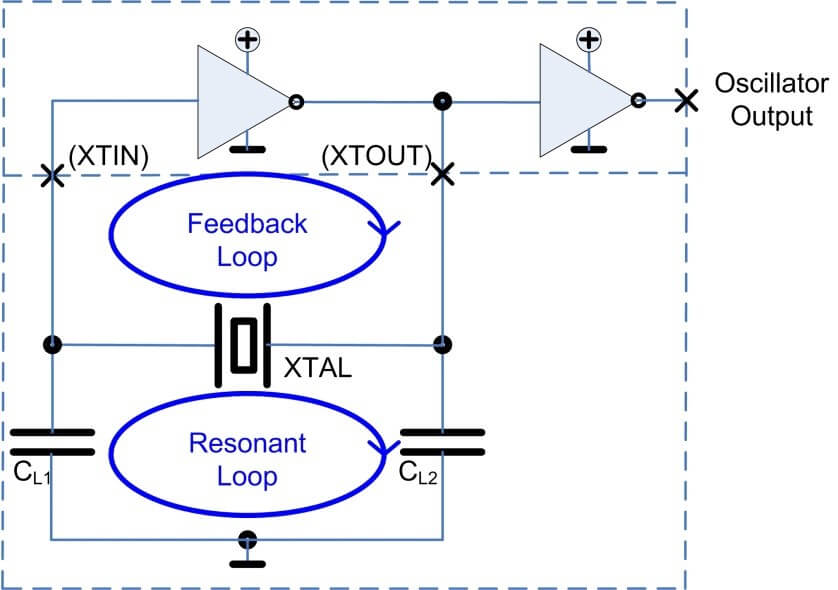

“A quartz crystal is best suited when the developer wants to build their own electronic oscillator, allowing them to tune or optimize all the relevant parameters. This of course requires a certain amount of effort: The electronic oscillator has to be built and adapted to the resonator in order to ensure oscillation stability as well as cohesion over the entire operating temperature range,” explains Product Manager Leonie Weißer. Circuit components include, for example, capacitors, which must be selected so that the quartz crystal’s specific load capacity is achieved. If this is not the case, considerable deviations from the specified nominal frequency may occur. The specifications for the quartz crystal must therefore be clearly defined in advance to avoid frequency deviations.

However, since quartz crystals are less expensive than crystal oscillators, they are a better choice for larger quantities. In addition, there must be sufficient space on the circuit board: A piezoelectric crystal with circuitry requires more space than a crystal oscillator.

The perfectly coordinated complete solution: The crystal oscillator

When using an oscillator, all components of the internally installed circuitry are already perfectly matched. In contrast to a quartz crystal with circuit, the oscillator usually takes up less space. An oscillator always contains a frequency control component—in our case, an quartz crystal. This is inserted into the Pierce circuit, which causes the quartz crystal to oscillate.

The oscillator is therefore the most space-saving alternative: Everything is compact and built into one component, and the developer does not have to design a circuit around the piezoelectric crystal. The component is particularly suitable for low volumes because it eliminates the need for time-consuming optimization and tuning of circuit components.

Another advantage of the oscillator is that when using a quartz crystal, the ratio of area to thickness must not fall below a certain value. If this ratio is not maintained, it will have a negative effect on the electrical parameters. This means that low frequencies (below 10 MHz) can no longer be handled in smaller designs. This limitation does not apply to oscillators because they have an IC inside. The same applies to circuits with higher frequencies—here, too, quartz crystals reach their physical limits more quickly. Due to the internal IC, compensations via temperature are also possible (TCXOs). This allows the developer more room to maneuver in order to meet the requirements of the respective application and its external influences. This leeway also allows a frequency stability of +-0.05 parts per million. At best, quartz crystals are specified with just under +-10 parts per million.

Need help selecting the right frequency control component for your application? Please get in touch with us so that we can find the right component for your application together.

Deutsch

Deutsch