Stay cool when it gets hot: Frequency control products from Jauch for high-temperature environments

As temperatures rise and the sun beats down on technology, it’s not only people who feel the heat – electronic components must also perform at their best. Frequency control products, such as quartz crystals and oscillators, are particularly critical in this regard. They ensure precise timing in countless applications – from GPS and Wi-Fi to

- Published in Frequency Control Products

Long service life and maximum frequency stability for insulin pumps and CGM systems

In Germany, around 400,000 people currently suffer from type 1 diabetes. Of these, around 35,000 children and young adults up to the age of 18 are affected. But what does the diagnosis “type 1 diabetes” actually mean? And what do diabetics need to consider after receiving their diagnosis? Which devices and systems help diabetics to

- Published in Battery Technology, Frequency Control Products

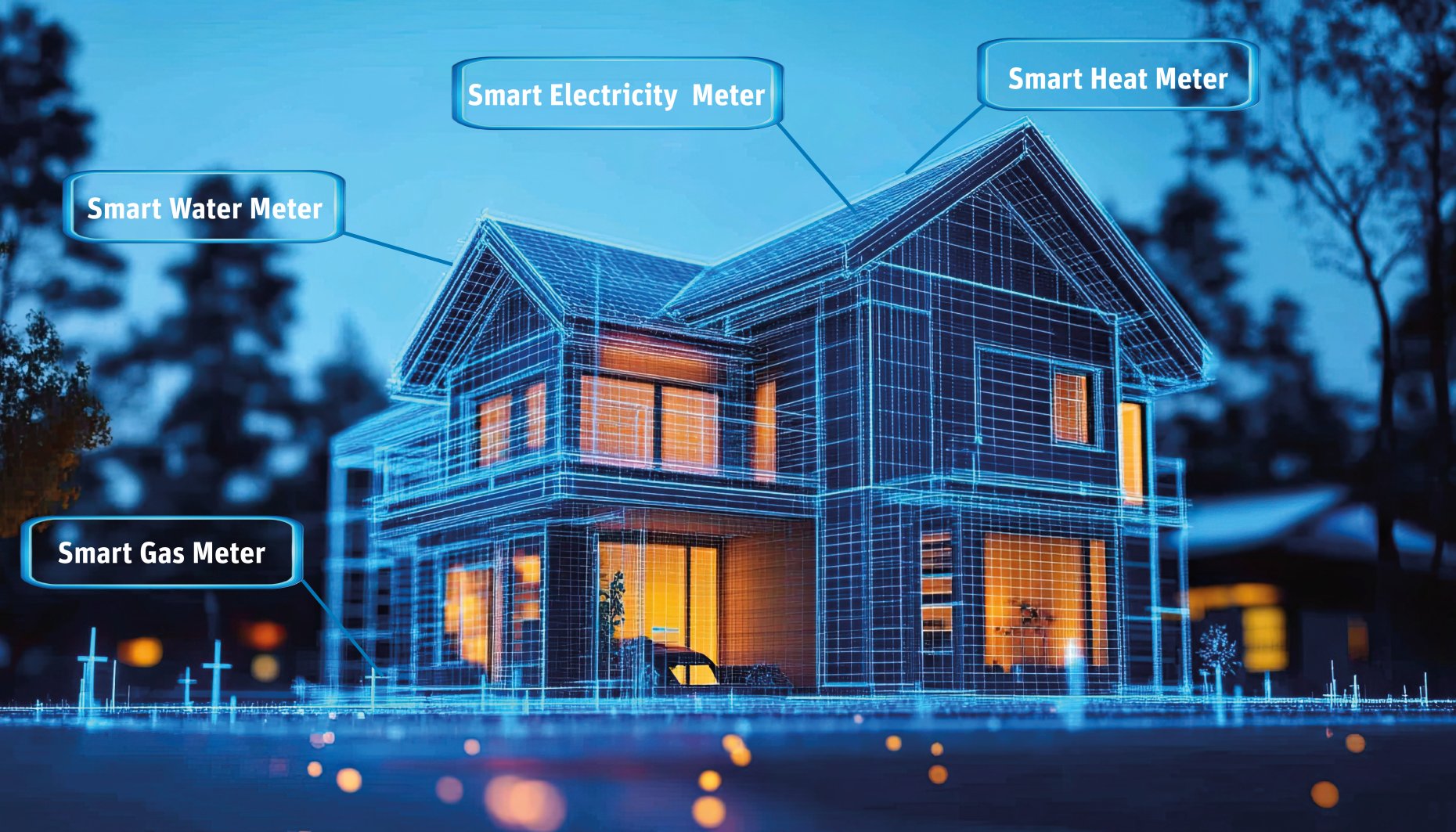

Why smart metering is the future of energy supply and why nothing works in this area without reliable frequency components and stable power sources

Everyone is talking about “smart metering”. But what exactly is this buzzword all about? And why would this technology be pretty much useless without frequency-stable clocks and reliable power sources? By “smart metering”, we are talking about a technology that monitors and analyzes energy consumption in residential and commercial facilities in real time. “Smart meters”

- Published in Battery Technology, Frequency Control Products

Customer Success Story: Highest frequency stability for the tire pressure monitoring system sensor from TireCheck

A sensor that increases the safety of truck drivers and has a positive effect on the sustainability of tires – this is the mission pursued by TireCheck, a company specializing in the manufacture of tire management systems and tire pressure sensors for commercial vehicles. The product: the belt-mounted TPMS sensor One notable innovation from TireCheck

- Published in Customer Success Stories, Frequency Control Products

Ask the tech department: How thick is a quartz blank of 40 MHz?

Let’s start this blog post with a little quiz: Guess for yourself – the solution will come in the text. How thick is a quartz blank of 40 MHz? As thick as.. Guess for yourself – the solution will come in the text. But first, let’s take a look at the theory: Generally speaking, there

- Published in Frequency Control Products, Frequency Control Products

Stratum layers: an example for their necessity

It is Monday morning at 9:30 am. A selling order is placed on the exchange. Immediately after, two buying orders arrive for it. But there can only be one buyer. Who was faster and is eligible? How is fairness assured, and guaranteed without any risk of collision? The trading of shares determines the actions on

- Published in Frequency Control Products

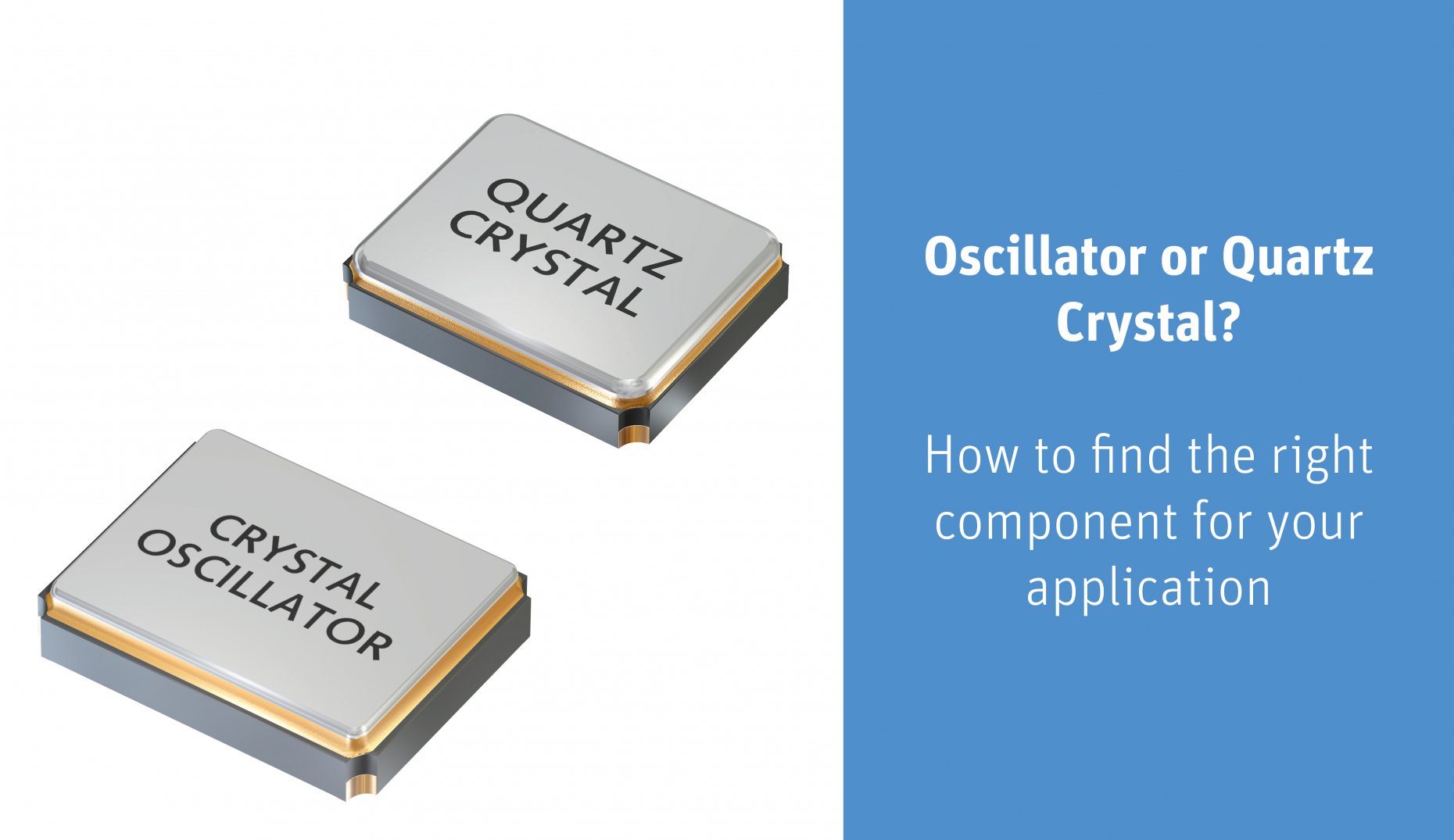

Oscillator or Quartz Crystal? How to find the right component for your application

In developing an electronic assembly, one of the steps involved includes choosing the appropriate frequency control product. The basic question at the outset is whether to install a quartz crystal or an oscillator. To reach the right decision, several parameters need to be considered. These include the many different requirements of the application, the device,

- Published in Frequency Control Products

Quartz Crystals and Oscillators in the Digitalization Trend

For several years now the term ‘Internet of Things’ has been in common parlance. Devices that are part of the ‘IoT’ can communicate with each other wirelessly. This is generally achieved using current standards such as WiFi, Bluetooth, Zigbee, and 5G. The Internet of Things also changes the requirements placed on the devices themselves. Today

- Published in Frequency Control Products

Compliance with the tolerance budget of applications: long-term aging must be taken into account

Each application has a tolerance budget in terms of frequency deviation that must be adhered to even in the worst case scenario in order to ensure that the application functions. Developers must therefore be aware of all factors that can lead to frequency deviations. The sum of all worst-case scenarios of these factors must not

- Published in Frequency Control Products

From assembly to the final product – the last stages in the quartz manufacturing process

In the blog posts Ask the Product Manager: Are real rock crystals used for production of oscillating quartz crystals? and Quartz production process: from quartz block to quartz blank, we have already taken a closer look at the first stages in quartz production, what material the quartz blanks are made of and what steps are

- Published in Frequency Control Products

Deutsch

Deutsch